You are challenged to differentiate yourself amidst global competition and rapidly evolving technology. Your customers demand innovative solutions that increase business agility, optimize productivity, and achieve sustainability objectives. All of this, while they look for every way possible to lower their total cost of ownership.

We can help improve your performance to lower the Total Cost to Design, Develop, and Deliver machinery and meet customer requirements. Our industrial control system design and engineering solutions help you:

- Define value beyond machine and equipment costs

- Maximize performance

- React quickly to change

- Increase profits

- Innovate and attract new customers

Design Infrastructure

Lean Automation is one of the largest company focused on industrial automation and information, dedicated to making our customers more productive and the world more sustainable, tremendous importance is given to develop world-class designs, we follow industry-leading practices in design development, state of the art workstations are used by our team of experts for superior results, we develop designs which are technologically and commercially most effective variants, handle the design and planning work, and bring up the project to a successful conclusion at your chosen location, we take atmost responsibility for executing the entire project.

- T20+ Senior BIW design engineers

- Conference rooms for Design reviews

- Secure Server with Backup

- 1 FTP server for Data transfer

- 2 Mbps leased line for Internet

- Workstation & Mobile Workstations

Whether providing you with single components, entire systems, or specialized consultation, our goal is to offer personalized solutions.

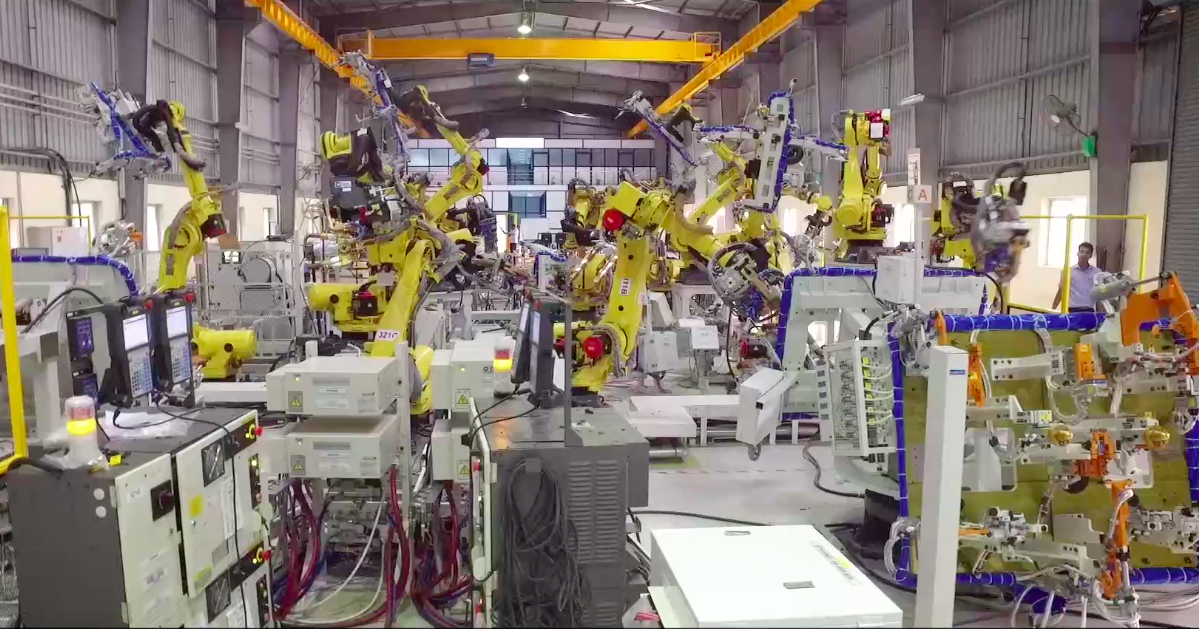

Lean Automation is largely involved in Intelligent manufacturing research focuses on intelligent manufacturing systems, modelling and design of distributed artificial intelligence for manufacturing shop floor, networks and supply chain management and optimisation, and holonic manufacturing systems.

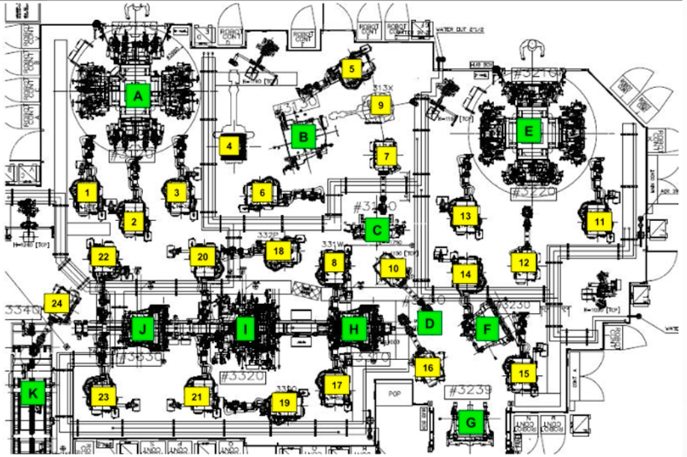

- Total Shop Floor Area of two plants of 30,000 sq ft for assembly & trials

- Office Space of 5000 sq ft

- MSEB Power 200 KVA and 250kva

- 150KVA and 65KVA Generator for power back up

- Stabilized weld power for Robotic Trials

- Machine Shop for rework activity during Assembly & Inspection

- Paint Shop

- Air Compressor 10 and 7.5Bar with Drier Unit

- Weld Deck for manual weld trials with water circulation for weld guns

- Overhead Crane of 30 MT and 5MT

- Manual Fork Lift of 1MT

- 2 Faro Arms of 2.4m & 3m for Jig / Fixture Inspection

Manufacturing Infrastructure

We have the expertise to meet your unique industrial automation challenges anywhere in the world, to remain competitive in the global marketplace, many companies are shifting from product-driven operations to customer-centric, demand-driven manufacturing environments, Reliability & efficiency are essential in manufacturing industrial equipment, we streamline implementation and extend the value of your solution with increase in demand for greater output your lines ability to perform consistently is the key to production success, once your line up is up and running our support continues every step of the way, atmost care is taken up for successful commissioning, and also during the product life-cycle.